Special Anti-Vibration Mounts

Advanced Solutions for Vibration Control

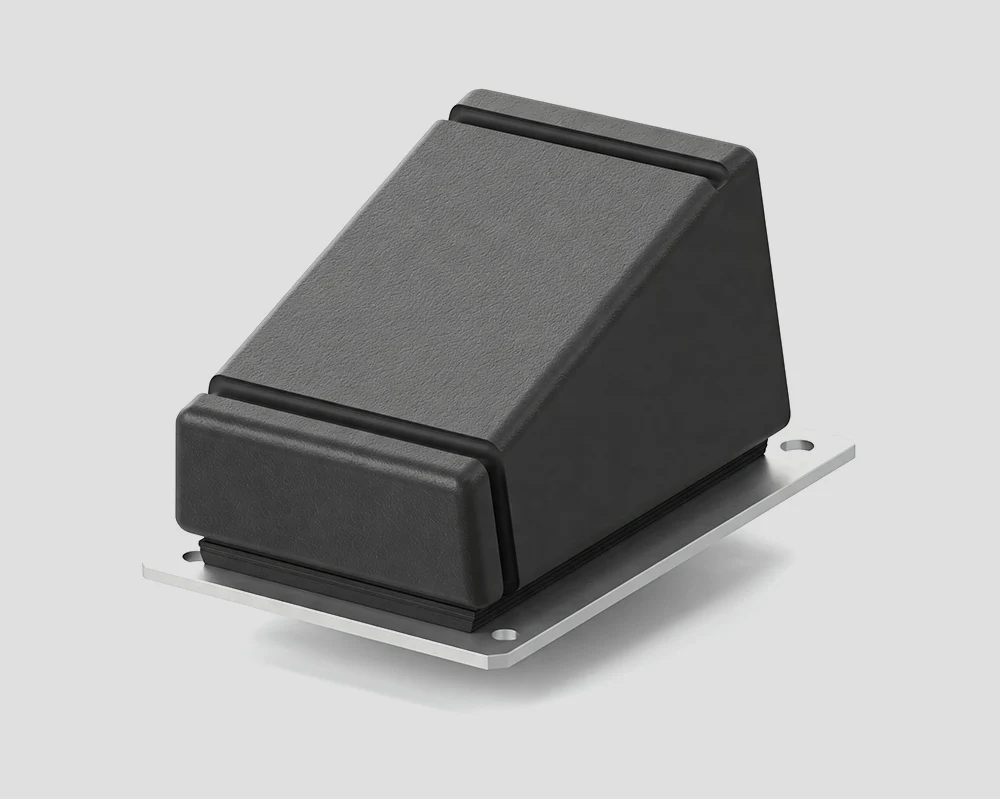

Special anti-vibration mounts are devices designed to reduce, isolate, and control vibrations in industrial, automotive, railway, aerospace, and many other applications. These advanced components are made from high-quality elastomeric materials—such as rubber, silicone, or rubber-metal composites—selected for their durability, strength, and performance under extreme conditions.

What Are Special Anti-Vibration Mounts?

These mounts are engineered solutions to isolate or dampen vibrations, helping reduce damage from mechanical stress and noise. They are essential in systems where vibrations and noise can compromise safety, functionality, or equipment life. Their ability to perform under extreme conditions—such as high temperatures, corrosive environments, or heavy loads—makes them highly reliable.

Types of Special Anti-Vibration Mounts

Elastomeric Mounts (Rubber Springs)

Designed to absorb and isolate vibrations from machinery or mechanical systems. Made from rubber or special elastomers, they offer an optimal balance of elasticity and mechanical strength.

Anti-Vibration Pads

Primarily used to dampen vibrations in high-speed industrial applications, such as in the automotive and railway sectors. These pads can be made with composite materials to ensure superior performance in harsh environments.

Rubber-Metal Isolators

These combine the properties of rubber and metal, offering excellent mechanical resistance and high vibration isolation. They are ideal for demanding applications in the automotive, marine, aerospace, and construction industries.

Anti-Vibration Mats and Plates

Designed to reduce vibrations in machinery and industrial systems. These are made from elastomeric materials and can be customized in size and shape to fit specific applications.

Features and Benefits

Excellent damping capacity

Special anti-vibration mounts are designed to significantly reduce vibrations, minimizing component wear and improving operational reliability.

Resistance to extreme conditions

Thanks to advanced materials such as silicone, special elastomers, and rubber-metal composites.

Reliability in harsh environments

Special anti-vibration mounts are capable of operating in environments with high temperatures, exposure to chemical agents, or conditions of heavy mechanical stress.

Noise reduction

In addition to reducing vibrations, these components help decrease structural noise, improving the work environment and complying with industrial noise regulations.

Customization

Special antivibration components can be custom-designed for specific applications, adapting to the requirements of load, frequency, and the type of vibrations to be dampened.

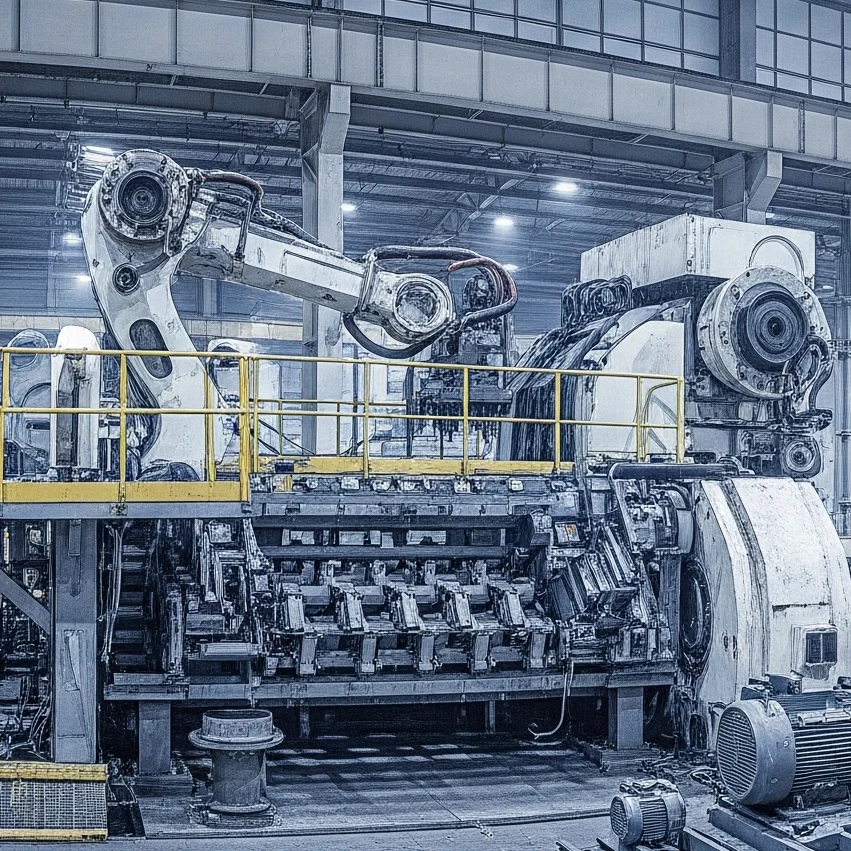

Applications

Special antivibration components are used in a wide range of industries where vibration control is crucial to improve performance, ensure safety, and extend the lifespan of machinery. Below are some of the main sectors.

For food contact components, ask

Special Rubber.

Special Rubber can support customers during the R&D phases of products and materials, project development, consulting, product design, and co-design. We offer a wide range of certified or certifiable compounds and materials for the relevant sector thanks to partnerships with qualified suppliers. We also assist customers throughout all stages of certification and approval of the finished product with laboratories and third-party organizations.

Special anti-vibration mounts offer advanced solutions for vibration control, enhancing reliability and extending equipment life. With high-performance materials and innovative damping technologies, they meet the demands of multiple industries with superior performance and maintenance cost reduction.