Custom Gaskets by Design

Tailored Solutions for a Perfect Seal

Custom gaskets by design represent a highly personalized solution to ensure impermeability, protection against vibrations, and thermal and acoustic insulation across a wide range of industrial applications. Thanks to the possibility of being designed and manufactured according to exact specifications, custom-designed gaskets meet the needs of industries requiring bespoke solutions, delivering superior performance in complex and high-stress environments.

What Are Custom Gaskets by Design?

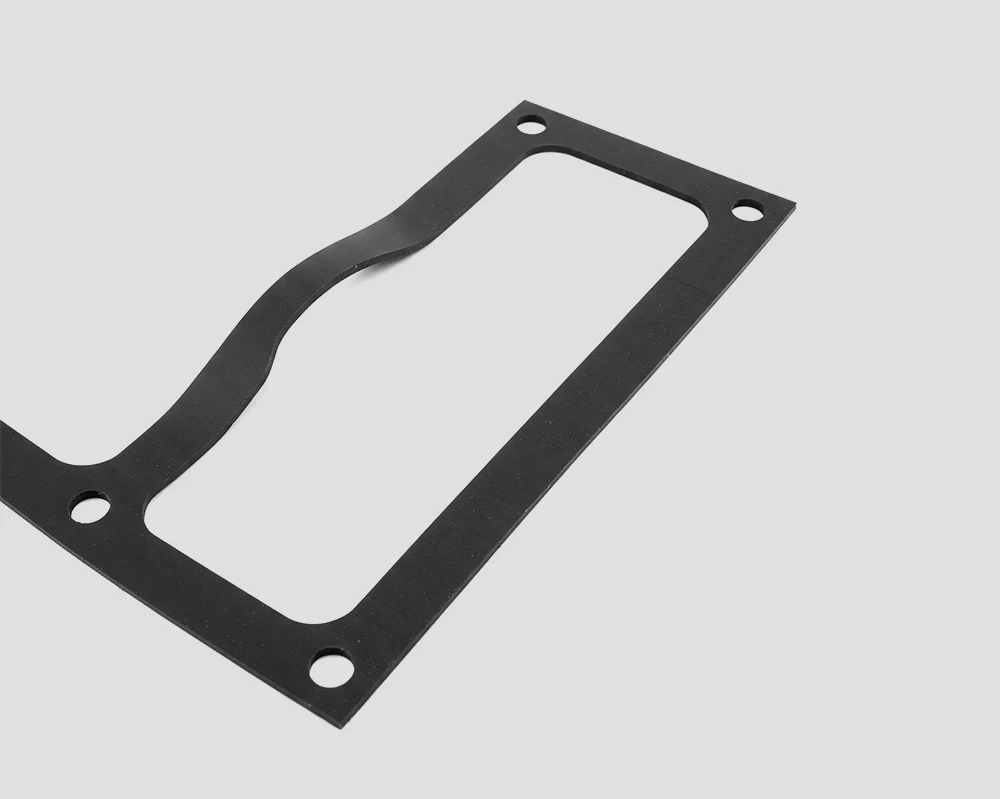

Custom gaskets by design are personalized components created to perfectly match the geometries and specific needs of an application. Unlike standard gaskets, which come in predefined shapes and sizes, custom gaskets are made to order based on technical drawings and precise dimensions provided by the customer.

These components are engineered to provide optimal sealing, both on flat surfaces and complex geometries such as flanges, through holes, containment tanks, and other industrial elements. Custom gaskets can be manufactured with very tight tolerances and tailored shapes, making them ideal in environments where standard gaskets are not suitable.

Materials Used for Custom Gaskets by Design

Custom gaskets by design can be made from a wide variety of materials suitable for different operating conditions, including extreme temperatures, exposure to aggressive fluids, or soundproofing requirements. The most commonly used materials include:

Rubber and Elastomers

Rubber gaskets are widely used and can be produced from various elastomers such as NBR (Nitrile), EPDM, SBR, Viton, and Silicone to ensure resistance to high temperatures, chemical exposure, and to maintain flexibility. They are ideal for applications requiring good elasticity and resistance to deformation.

Manufacturing Technologies for Custom Gaskets

Custom-designed gaskets are manufactured using different techniques depending on the material and the complexity of the required design. The main production technologies include:

Compression or Injection Molding

Mainly used for elastomeric and rubber materials, this process involves custom molds to produce gaskets with complex shapes, while meeting very tight dimensional tolerances.

Waterjet Cutting

Waterjet cutting is a technology that uses a high-pressure stream of water mixed with abrasives to cut through even thick materials like elastomers, foams, expanded polymers, or plastics.. It is ideal for producing gaskets with complex shapes.

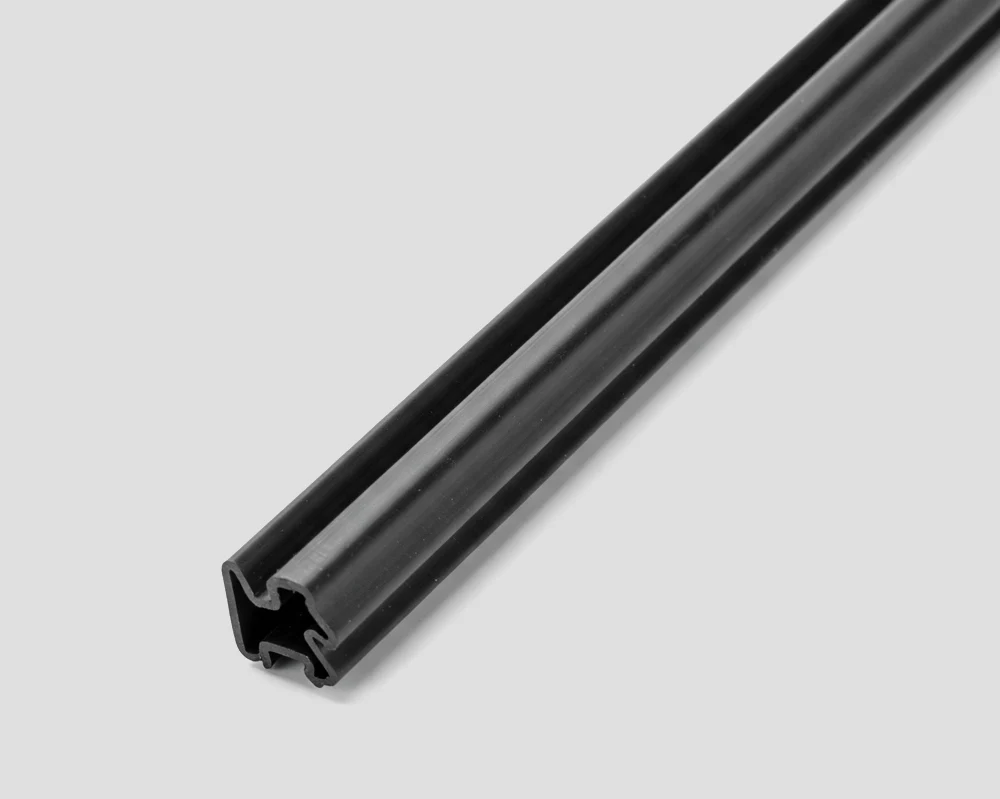

Extrusion and Co-Extrusion

In the case of rubber or silicone gaskets, extrusion enables the production of gaskets in different shapes and cross-sections, including custom shapes and special profiles.

CNC Milling

For metallic gaskets or high-precision materials, CNC milling allows for the creation of complex shapes with millimeter-level tolerances, making it suitable for applications requiring high performance.

Advantages of Custom Gaskets by Design

Custom-designed gaskets offer several advantages over standard gaskets, including:

Total Customization

Gaskets can be tailor-made to perfectly fit the specific geometries and needs of any application, ensuring an optimal seal and minimizing the risk of leaks or damage.

High Precision and Tight Tolerances

Thanks to modern manufacturing techniques, gaskets can be produced with extremely tight tolerances, ideal for high-precision applications such as in the automotive, aerospace, or energy sectors.

Versatile Material Selection

Custom gaskets can be made from a wide range of materials, each selected according to the application’s operating conditions, whether for thermal, chemical, mechanical resistance, or other specific properties.

Durability and Strength

Custom design and production ensure that the gaskets can withstand high stresses such as extreme temperatures, pressure, vibrations, or exposure to aggressive fluids—boosting equipment lifespan and reliability.

Cost Optimization

Although the initial investment for custom gaskets may be higher than for standard ones, their use reduces long-term costs associated with maintenance, failures, and downtime.

Applications of Custom Gaskets by Design

Custom-designed gaskets are used in a wide variety of industrial sectors thanks to their ability to meet specific needs and provide tailored technical properties. Key sectors of application include:

For Custom Gaskets by Design, ask

Special Rubber.

Special Rubber can support customers during the R&D phases of products and materials, project development, consulting, product design, and co-design. We offer a wide range of certified or certifiable compounds and materials for the relevant sector thanks to partnerships with qualified suppliers. We also assist customers throughout all stages of certification and approval of the finished product with laboratories and third-party organizations.

Custom gaskets by design are advanced solutions that meet the most complex sealing and protection requirements in technical and industrial environments. Thanks to their customization, they ensure superior performance, improving the reliability of the systems they are installed in.