Food Contact Components

Safety, Quality, and Regulatory Compliance

Food contact components are critical to ensuring safety, hygiene, and quality throughout food production, processing, and distribution. From gaskets to processing equipment, these components must be made from safe, certified materials capable of withstanding the challenging conditions of the food industry, such as high temperatures, moisture, and contact with various chemicals.

What Are Food Contact Components?

These include all items and materials that come into direct or indirect contact with food.

Types of components for food contact applications

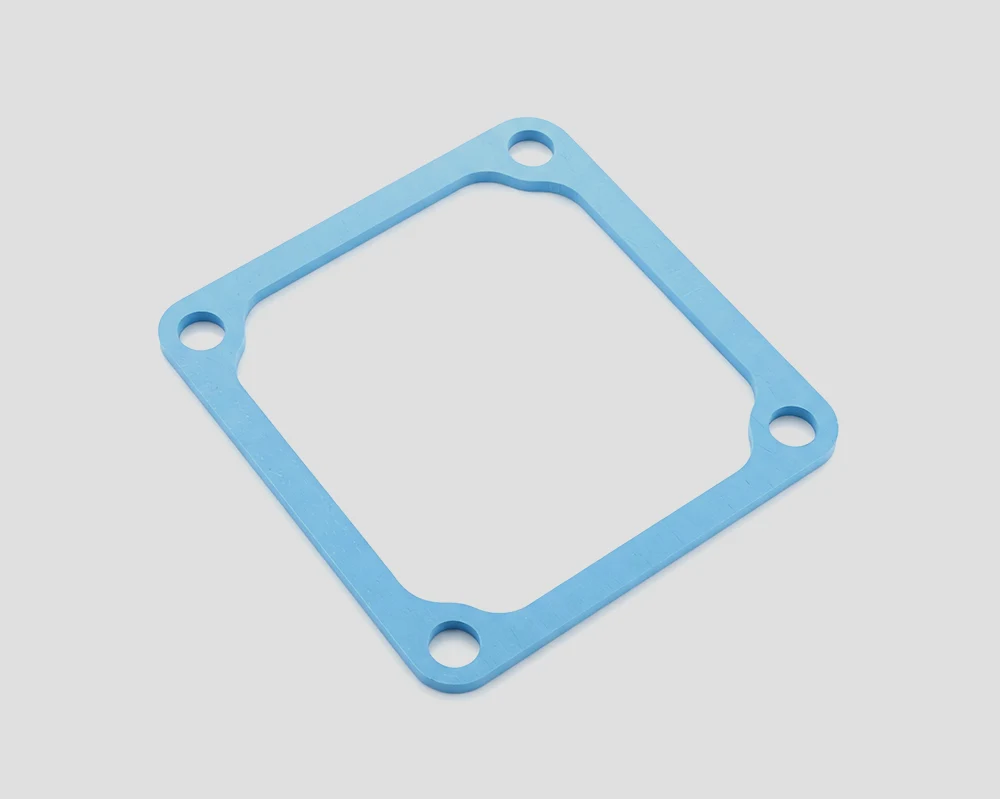

Gaskets

For sealing joints and pipelines in equipment and containers.

O-rings and seals

Ensuring leak-proof systems for fluid transfer.

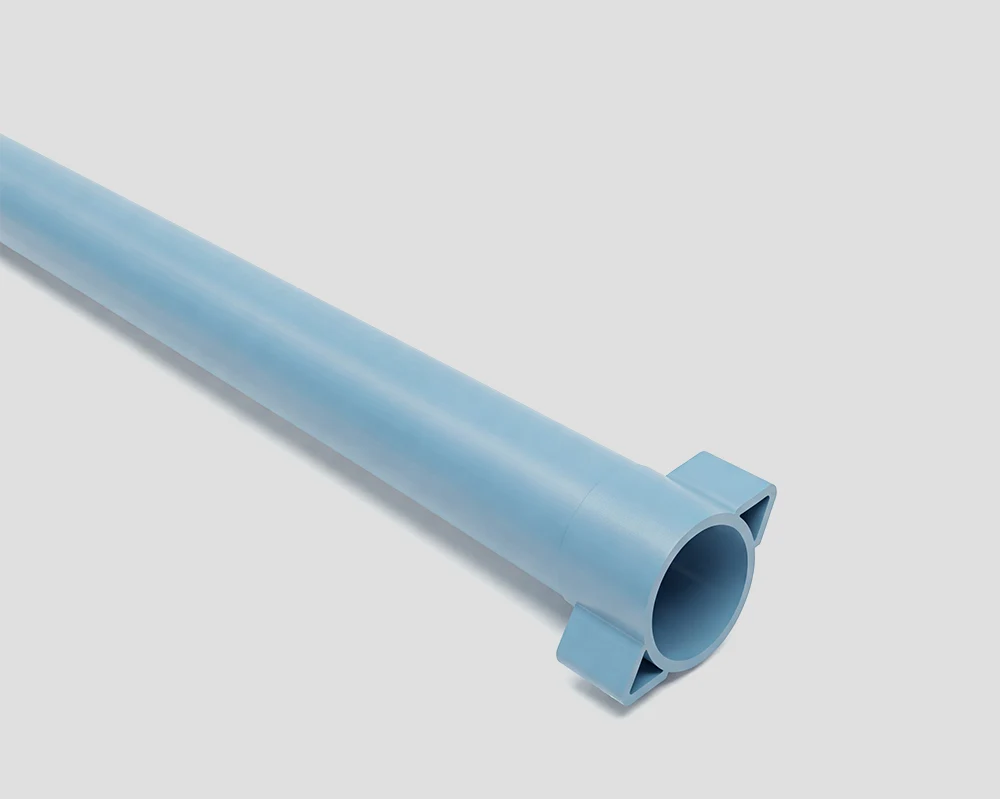

Fittings and piping

For transporting food-related liquids or gases.

Tools and equipment

Such as spatulas and packaging machines, designed for safe use and easy cleaning.

Miscellaneous parts

Used in food handling and processing machinery.

Materials Used

Plastic

(PE, PP, food-grade PVC)

Requires certification and must not contaminate food.

Stainless Steel

Corrosion-resistant, durable, and easy to clean; used in machinery and piping.

Silicone

Heat-resistant and non-toxic; used for gaskets, baking molds, and tools.

Rubber

Resistant to oils and fats; ideal for specific food processing needs.

PTFE

(Teflon)

Chemically resistant, low-friction, used in seals and coatings.

Aluminum

Lightweight, durable, used in food packaging (e.g., cans, foils).

Reference regulations for food contact items

Consumer safety and health are top priorities when it comes to materials intended for food contact. To ensure that these items do not contaminate food, a series of safety regulations and standards have been established. The main regulations include:

Regulation (EC) 1935/2004

This regulation sets out the general requirements for materials intended to come into contact with food within the European Union, ensuring that they do not release hazardous substances during use. Materials must be manufactured in a way that does not endanger consumer health or alter the properties of the food.

Regulation (EU) No 10/2011

It regulates plastic materials intended for food contact, defining safety requirements for polymers and resins. It also specifies the migration of substances from plastic materials into food, setting limits for contaminants.

FDA (Food and Drug Administration - USA)

In the United States, the FDA regulates food contact materials through 21 CFR Part 177, which sets safety guidelines for plastics, rubber, metals, and other substances used in the food industry.

NSF/ANSI 51

This certification is specific to food contact materials, ensuring that the materials and products meet the safety, durability, and quality requirements of the food industry.

ISO 22000 e ISO 9001

These international standards relate respectively to food safety management and quality management, and are often applicable to manufacturers of items intended for food contact.

Applications of Food Contact Items

Food contact items are used in various industrial applications, including:

Benefits of Certified Food Contact Products

Guaranteed food safety and hygiene

The use of materials compliant with regulations prevents contamination risks and ensures the safety of food products.

esistant to harsh conditions

These items are designed to withstand high temperatures, humidity, and the mechanical and chemical conditions typical of food production lines.

Easy cleaning and maintenance

The materials used are designed to ensure easy cleaning and prevent the growth of bacteria and contaminants, reducing the risk of cross-contamination.

Long service life and reduced downtime

Certified items are durable and long-lasting, reducing maintenance and replacement costs while increasing production efficiency.

For food contact components, ask

Special Rubber.

Special Rubber can support customers during the R&D phases of products and materials, project development, consulting, product design, and co-design. We offer a wide range of certified or certifiable compounds and materials for the relevant sector thanks to partnerships with qualified suppliers. We also assist customers throughout all stages of certification and approval of the finished product with laboratories and third-party organizations.

Food contact items are essential components to ensure safety, quality, and hygiene in the food industry. Choosing safe materials that comply with regulations is crucial to prevent contamination and protect consumer health. Investing in certified, high-quality items is fundamental for the success of any food business, ensuring safe, compliant, and reliable products at every stage of production.