Industrial Suction Cups

Solutions for Lifting and Automated Handling

Industrial suction cups are essential devices used for handling objects, lifting, and transferring materials safely and efficiently. Thanks to their ability to create a vacuum through suction, these tools enable fast and precise movement of loads, reducing the risk of material damage and improving operational efficiency in automated processes.

In this article, we will explore the main features, types of suction cups, their advantages, and applications across various industrial sectors.

What Is an Industrial Suction Cup?

An industrial suction cup is a device that uses the vacuum principle to exert a suction force on an object. Once the cup is applied to the load’s surface, the vacuum creates a grip that allows the object to be lifted, moved, or positioned without the need for direct mechanical contact. Industrial suction cups are used in a wide range of applications, including assembly processes, material handling, and packaging.

How suction cups work:

The suction cup is typically connected to a vacuum pump or vacuum generator, which removes air from the inside of the cup, creating a pressure difference between the upper and lower sides. This pressure differential generates the suction force that allows the cup to securely adhere to the surface of the object to be lifted.

What Is an Industrial Suction Cup?

There are several types of suction cups, each designed to meet specific handling and lifting requirements. The main categories of industrial suction cups include:

Rubber Suction Cups

Rubber suction cups are among the most commonly used due to their flexibility, durability, and ability to conform to irregular surfaces. They are ideal for lifting heavy loads or items with uneven surfaces, such as boxes or packaged materials.

Silicone Suction Cups

Silicone suction cups are particularly resistant to high temperatures and chemical agents, making them ideal for applications in extreme environments such as the food, pharmaceutical, and automotive industries.

Polyurethane (PU) suction cups

Polyurethane suction cups are resistant to wear, abrasion, and chemicals. They are often used to handle hard and heavy materials, such as metal sheets or electronic components, thanks to their robustness and durability.

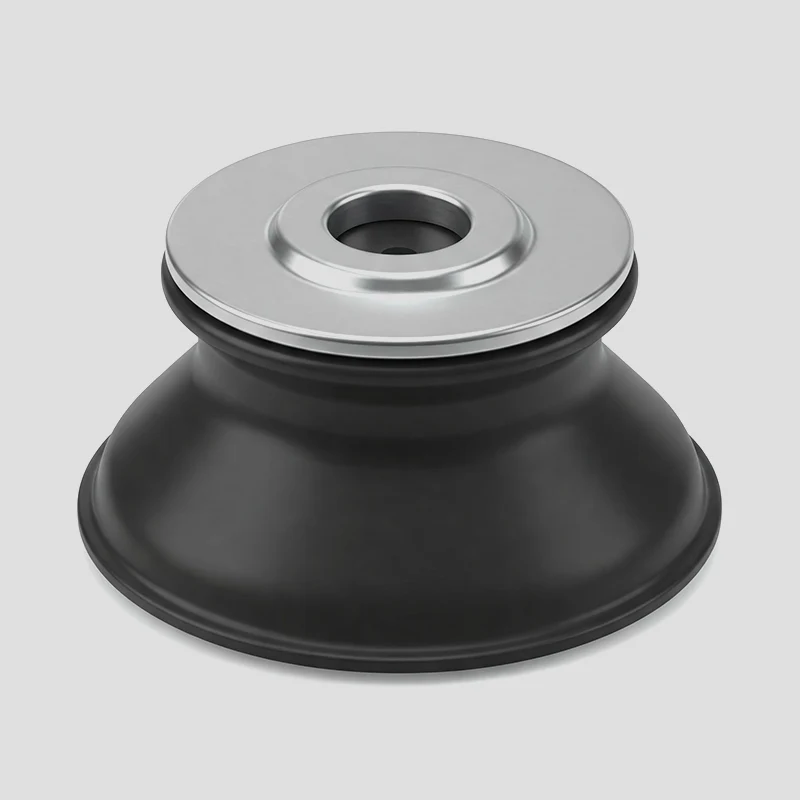

Vacuum dome suction cups

Dome-shaped suction cups, with a semicircular form, are designed for optimal grip on flat or curved surfaces and are commonly used for lifting glass sheets, plastic materials, or large panels.

Disc suction cups

Disc suction cups have a flat shape and are mainly used for objects with flat surfaces. They are very common in industrial automation systems for lifting components on production lines.

Long-life suction cups

Some models are designed to withstand particularly harsh working conditions, such as high temperatures, aggressive chemical environments, or continuous mechanical wear. These models are made from high-performance materials to ensure an extended service life.

Advantages of Industrial Suction Cups

The use of suction cups in industrial operations offers numerous advantages that help improve efficiency and safety in lifting and handling processes. Some of the main benefits include:

Increased efficiency

Suction cups reduce the handling and moving time of loads, allowing production lines to be faster and more productive.

Reduction of damage

Since suction cups never come into direct contact with the object's surface, they significantly reduce the risk of damage during lifting, which is especially important for fragile materials such as glass or electronic components.

Improved Safety

The use of suction cups automates lifting, reducing the need for manual intervention and minimizing the risk of injuries in the workplace, especially during operations involving heavy or difficult-to-handle loads.

Versatility

Suction cups can be used to lift a wide variety of materials, including smooth, rough, heavy, light, fragile, and sturdy objects, thanks to their ability to be adapted to the shape and characteristics of the load.

Compactness and simplicity

Suction cup systems are generally easy to install and maintain, occupying relatively little space and integrating seamlessly into industrial automation systems.

Applications of Suction Cups for Industry

Industrial suction cups are used in numerous sectors for a variety of applications, ranging from manufacturing to packaging, as well as automation and the food industry. Some of the main applications include:

Ask

Special Rubber

Special Rubber can support customers during the R&D phases of products and materials, project development, consulting, product design, and co-design. We offer a wide range of certified or certifiable compounds and materials for the relevant sector thanks to partnerships with qualified suppliers. We also assist customers throughout all stages of certification and approval of the finished product with laboratories and third-party organizations.

Industrial suction cups are essential tools for the automated handling and lifting of materials across a wide range of industrial applications. Their ability to reduce production times, enhance safety, and improve precision in lifting operations makes them indispensable components in advanced automation systems. Thanks to their versatility, suction cups can meet the demands of multiple sectors, providing efficient and reliable solutions for every type of application.